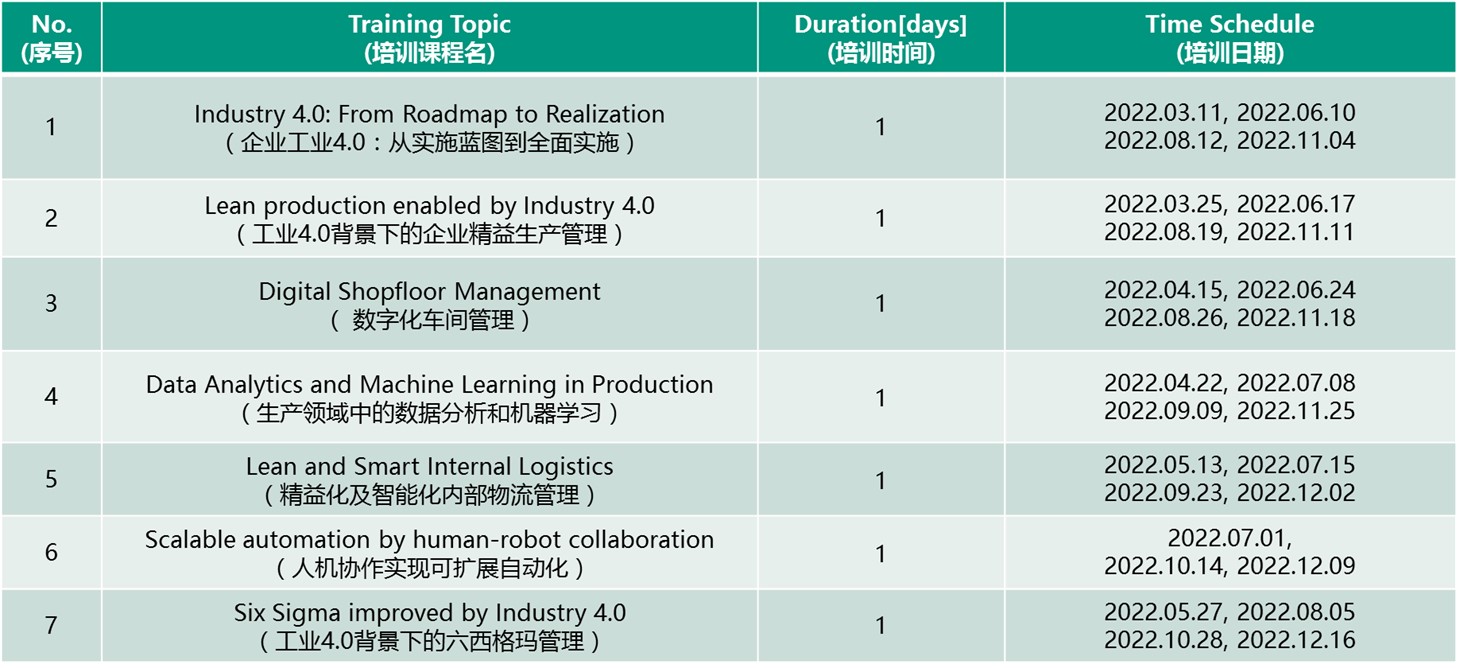

In the era of Industry 4.0, the toolbox of Lean Production is extended by new digital technologies. This training explains the origins and interrelations between Lean Production and Industry 4.0. The philosophy of lean production still is the baseline for identifying digital solutions that add value to your business. In this course, participants will be inspired by a broad overview of state-of-the art technologies, related to real-world challenges in production systems. Support is given on how to assess your value streams to find the right pain points to start with.